Tech Specs

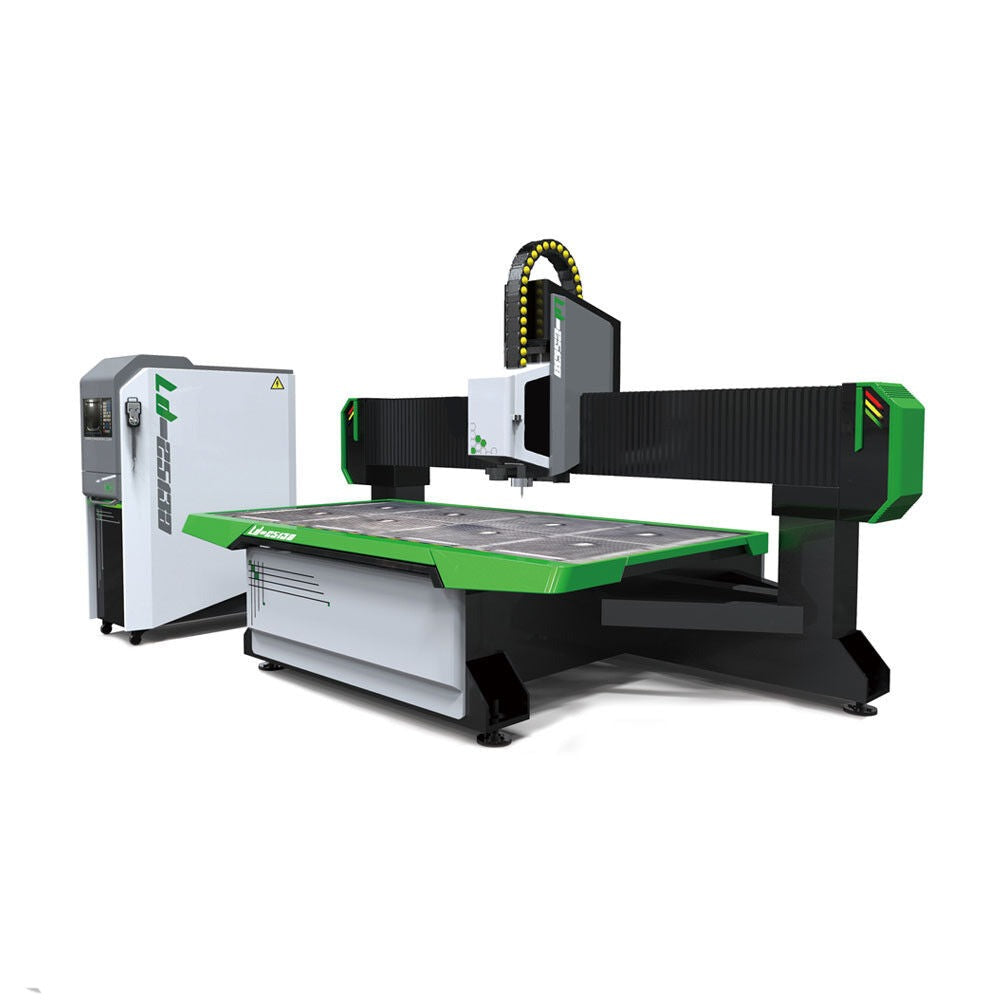

98" x 51" (2500mm x 1300mm) cnc router Machine, with Italy 9KW Spindle(ATC) and Vacuum System

| DETAILED CUTTING INFORMATION OF CNC ROUTER MACHINES | |||||

| No. | Material | Thickness range(mm) | Thickness(mm) | Speed(m/min) | Remark |

| 1 | acrylic | ≤ 50mm | 10mm | 12 | |

| 20mm | 6-8 | ||||

| 30mm | 4-6 | ||||

| 50mm | 2-3 | ||||

| 2 | MDF | ≤ 50mm | ≤ 20mm | 25 | |

| 30mm | 15 | ||||

| 50mm | 5 | ||||

| 3 | aluminum | ≤ 40mm | ≤ 5mm | 10 | |

| 10mm | 5 | ||||

| 20mm | 3 | cutting by layer | |||

| 30mm | 2 | ||||

| 40mm | 1 | ||||

| 4 | copper | ≤ 10mm | ≤ 5mm | 2 | |

| 10mm | 1.5 | ||||

| 5 | alucobond | ≤ 20mm | 20mm | 15 | |

| 6 | bakelite plate | ≤ 20mm | 20mm | 5 | |

| 7 | ABS plate | ≤ 20mm | 20mm | 5 | |

Features:

· Service life of machine up to a maximum of 20 years.

· The machine comes standard with 4 imported knife, automatic tool change, save manual tool changing time, improve work efficiency

· Suction pressure integration platform, 7.5KW vacuum pump equiption, the pump is assembled with relief valve and silencer, fix well material, In the working process the material does not vibrate, so it can improve the cutting surface finish.

· The double-check lathe bed pass anneal and heat treatment, to ensure that the use of solid shape.

· A world-class transmission YASKAWA servo drive motor with high speed and precision drive achieve a maximum speed of 5000 / rpm, also uses a high-resolution serial encoder (16,17bits) to improve the positioning accuracy. Use D Q axis conversion current control system, torque control precision (repeatability) also increased by ± 5% to ± 2%.

· PMI 3220 XY axis adopt imported ballscrew with high precision and smooth transmission to improve the processing finish.

· Excellent electromechanical design and other electrical Accessories with famous international brands (Omron, Schneider).

· Gantry of fixing structure, transom fixed, moving platform, adopt imported gantry milling and planer finishing, improve the overall accuracy of the machine assembly.

· It has a breakpoint, continued carving capabilities.

·Intelligent protection work table to prevent the wrong operation and other possible surface damage. Intelligent processing cross-border protection, to prevent mechanical collision phenomenon caused by the design surface over the processing area.