Tech Specs

Description

The Xerox 2-Color M-Series Downfire Mercury Printhead (High Temp) enhances jetting performance across a wide array of materials used in industrial applications.

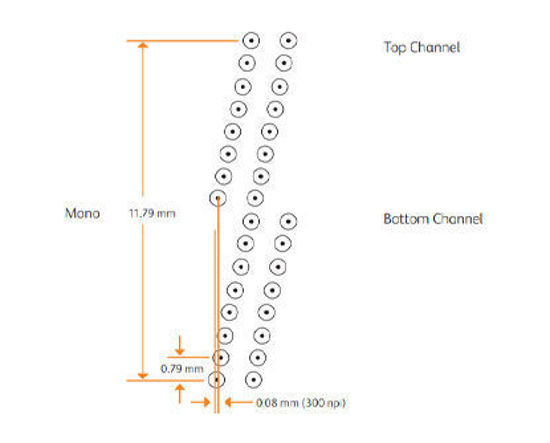

The MDF Printhead Assembly’s 880 jets are precisely aligned to one another during the manufacturing process. High nozzle-count systems require fewer printheads and simpler alignment mechanisms. The printhead can be operated at temperatures as high as 125°C. This further increases the latitude of jettable materials by allowing temperature to be used to adjust material viscosity to an appropriate level. With a maximum operating frequency of 43 kHz, the MDF Printhead Assembly provides superior throughput and performance.

We recommend to change the head cables when installing a new printhead.

Specifications:

- Number of addressable jets: 880

- Rows of nozzles: 16

- Nozzle spacing: 168.8 microns (150 npi)

- Drop size: 15-30 pl

- Normal drop velocity: 3.3 to 7.5 m/s

- Drop size variation, 1 sigma (with proper head calibration by customer): -2 percent

- Operating temperature: room to 125°C (257 F°)

- Fluid viscosity : 6 to 11 cP (higher/lower viscosities can be evaluated)

- Fluid surface tension : 25 to 40 dyne/cm

- Maximum operating frequency: 43 kHz

- Head filter : 25 microns absolute (removable filter)

- Wetted materials: 316L Stainless Steel Aluminum AL6061 E-coat Sylgard® 577 Trogamid® CX7323 Ultem® Plastic Kapton®

-

Ejection cycles successfully testes (waveform dependant) : 1.5 trillion (or more) drops per jet