Tech Specs

Description

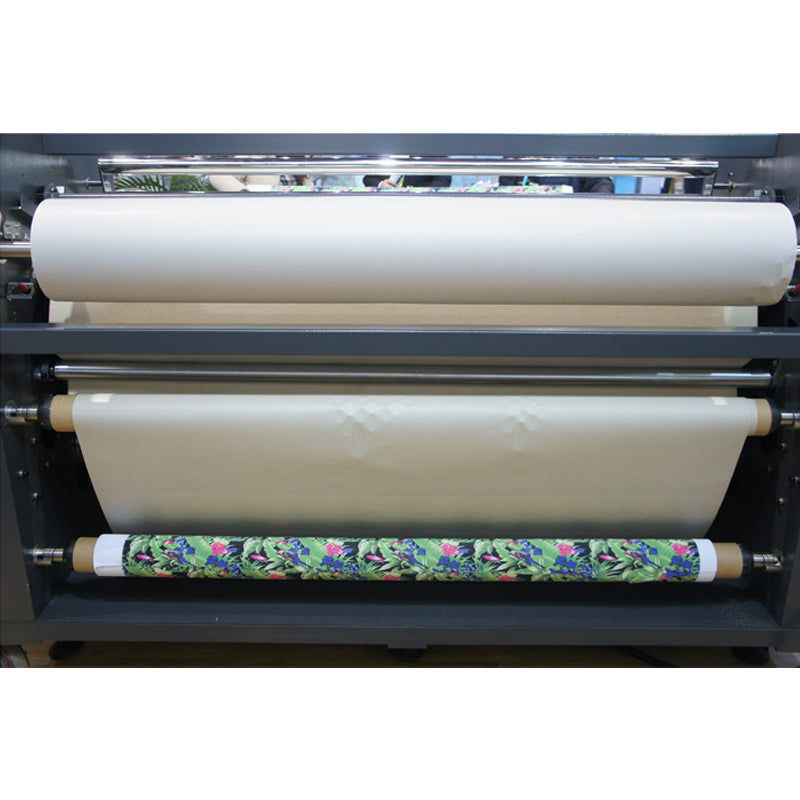

The Large Format Roll to Roll heat transfer machine 1700 (oil-warming machine) is the new type of heat transfer equipment, available for dye sublimation ink prints, oil heating. It fully represents the advantage of the speed and good elect in transfer printing. It adopts the oil heating mode to control the temperature, achieving speed in warming and good effect in the heat preservation, as well as improving the productivity. In addition, it has functions such as automatic blanket , automatic lifting backing paper and automatic rolling picture etc.

Specifications

Working width: 1700mm

Drum OD: 320mm

Speed: 0-4.2m/min

Power consumption: 18Kw

Stainless steel Heater Qty: 9pcs

Rated current: 30A

Motor: 750w

Weight: 1500kg

Blanket: Φ2422X1820Xδ6mm

Max OD unwind/rewind: 300mm

3" Alumininum shaft of unwind/rewind

Without air compressor

Characteristics

1. No cooling machine is needed and the blanket can be separated with the barrel.

2. Heating wheel is controlled by sealed and heat-oil heating to efficiently ensure the even and stable temperature.

3. Printing speed is equipped with continuous speed adjustment system, feeding equipment is convenient for operation with swiftness and high reliablity.

4. Roll to Roll transfer, Automatic blanket off, Automatic lifting off backing paper and Automatic rolling picture.

5. Low noise and stable speed.

6. Convenient operation with power-failure protection function.

7. Get CE Certificate.

Comparison

Our product: tight structure, practical in use, high automatization, and labor-saving, used for A Producting House.

Heating mode: oil heating

Drum OD: 320mm

Speed: 0-4.2m/min

Other brand (such as Guardian Calender USA): messy structure, platform support required, low automatization, labor-wasting, used for A small studio.

Heating mode: Infra-Red heating

Drum OD: 250mm

Speed: 0-1.08m/min

Working procedure

Usages

Suitable for printing on whole roll of fabric, seat pad, back pad, sleeping bag, handicraft fan, unbrell and hanging painting, and all kinds of fabric can be also ironed, pressed and folded.