1

/

of

1

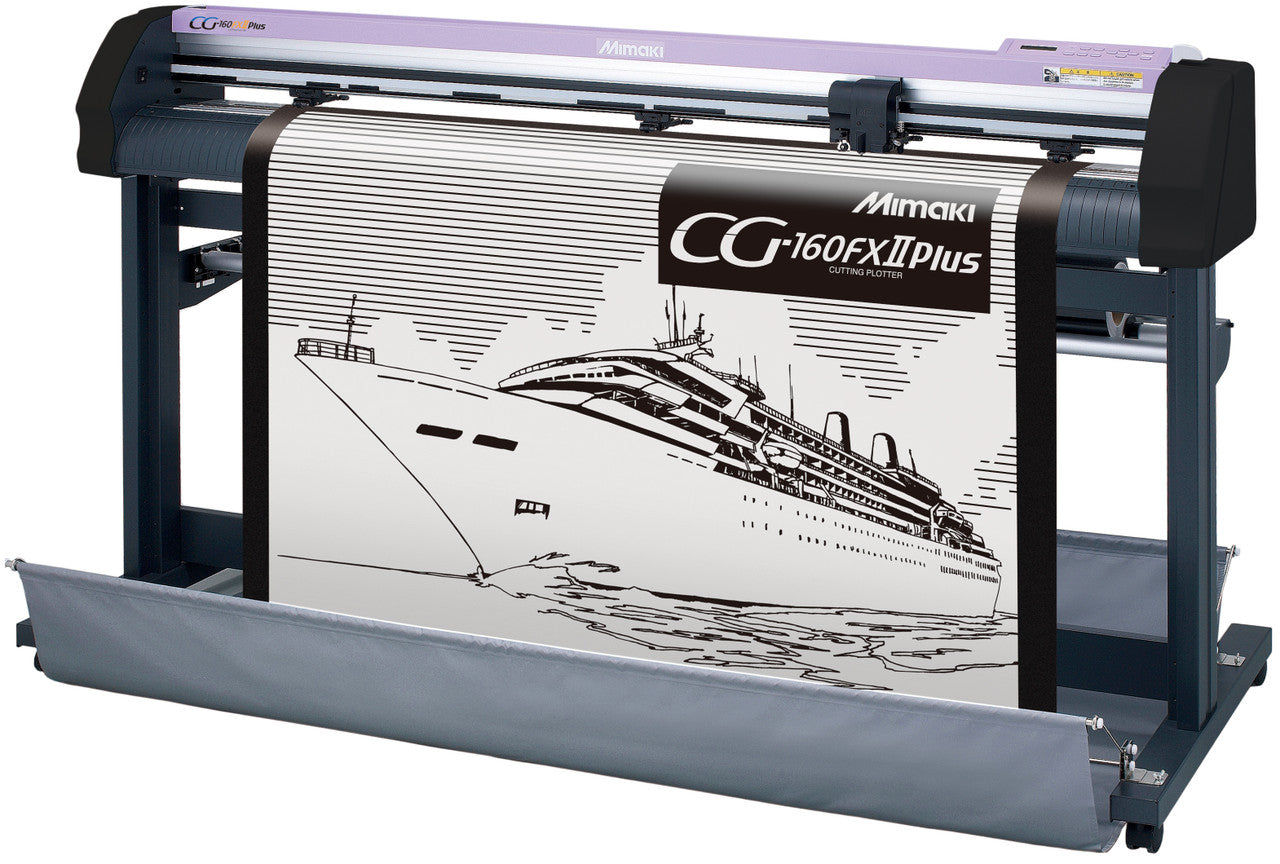

74" Mimaki CG-160FXII Vinyl Cutter with Stand

- Regular price

-

$6,795.00 - Regular price

-

- Sale price

-

$6,795.00

Shipping calculated at checkout.

Couldn't load pickup availability

74" Mimaki CG-160FXII Vinyl Cutter with Stand

- Regular price

-

$6,795.00 - Regular price

-

- Sale price

-

$6,795.00

Subscribe to our emails

Be the first to know about new collections and exclusive offers.