Tech Specs

Features:

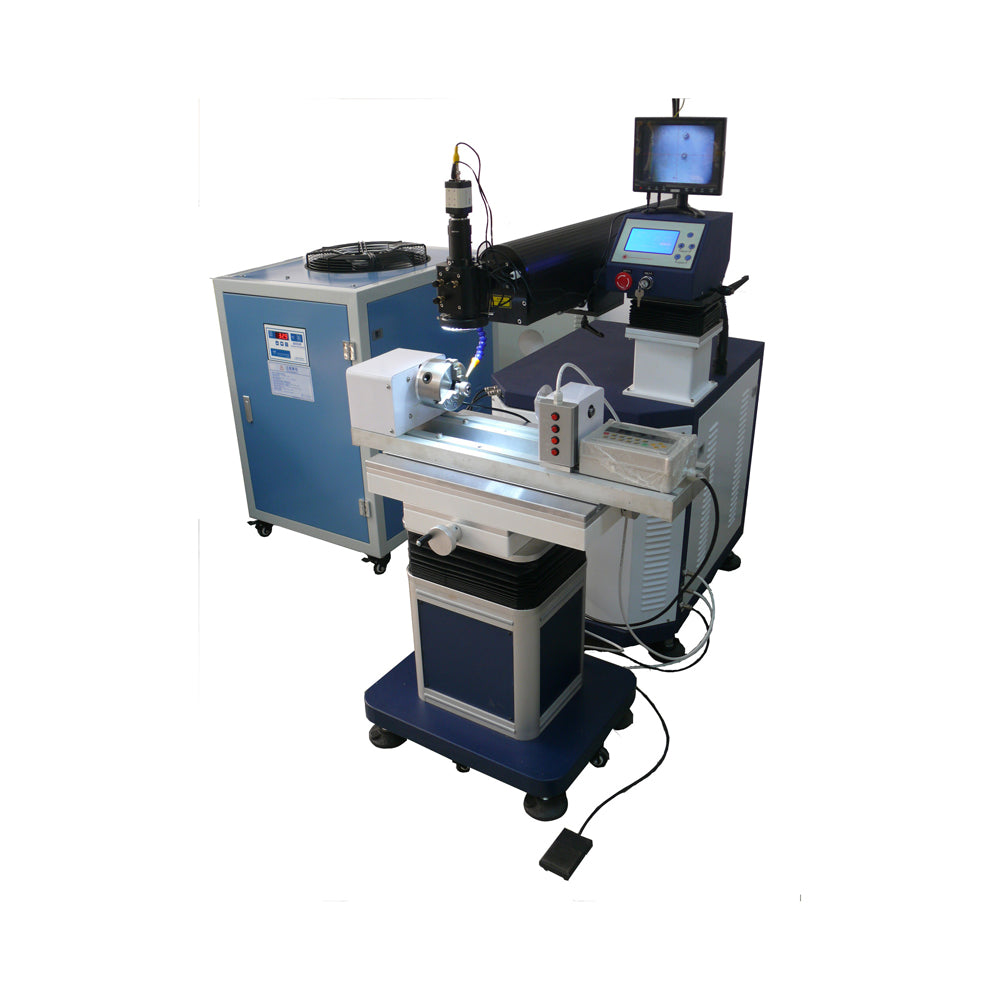

This machine features its small size, easy operation, firm and good-looking welded spots. It is suitable for repairing of different kinds of metal materials and can work for long time continuously, with small heated area and pollution free worksite. It can be used for welding different sorts of steel as used for making molds, beryllium copper, stainless steel, aluminum, platinum, K gold, silver and titanium and different metals and alloys.

• Welding point’s diameter only 0.1-3.0mm, with high precision and accuracy;

• Wavelength of YAG Laser is 1064nm which is less harmful to human skin compare to other laser

• Small heating scope ensures distortion free and bubble free work pieces

• Compensating the deficiency of traditional argon-arc welding and cold welding in repairing the fine surfaces; low oxidation effects and color change free for work pieces;

• Welding operations can be done within the small spaces or deep cavity areas, no damage will be caused to the surrounding walls. No distortion on the mold nor dents around the weld pool can occur.

• Edge won’t be damaged by burning when fine parts are repaired.

• Argon gas protection ensures the repairing parts and base materials won’t be burned nor oxidized.

• Joystick control, movable work piece, fitting and curve;

• Operations monitored by microscope, ensuring good vision of fine parts;

• Imported welding wires, fitting different kinds of imported mold materials, Polishing and texturing can also be realized.

• Processing cost can be greatly saved in terms of materials, labor and time consuming.

Specifications:

Laser Power: 400W

Laser Source: Pulsed Nd:YAG 8*155mm

Pulse Width: 0.3-20ms

Pulse Frequency: 0.1-100Hz

Beam Diameter: 0.1-3.0mm

Filler Wire Diameter: Max 0.8mm

Single Pulse Energy: 120J

Cooling System: 2P water chiller

Power Supply: 380V±10%/50Hz

Power Consumption: 12KW

Observing System: Microscope 10X

3 axis of table: X=300mm,Y=200mm,Z=150mm,XY manual, Z electrical

Data Memorization: 100 groups

Illumination: LED ring lights

Language Display: English

Shield Gas Supply: One line quick connection (argon)

Running Environment: Tem 5°C-30°C, Hum 5%-75%

Dimensions:1150 x 700 x 1300mm+850 x 550 x 670mm+980 x 800 x 1150mm

Weight: 150kg(welder)+70kg(table) +75kg(chiller)

Packing Size:1350*740*1400+680*590*890+730*650*1240mm

Gross Weight: 425kg